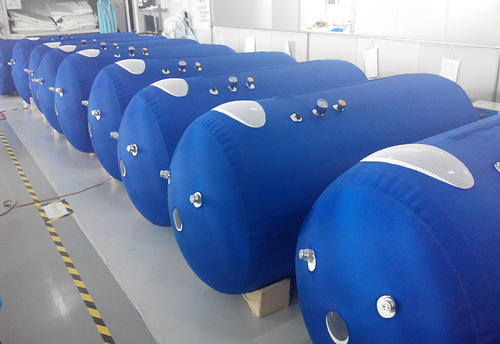

macypanhbot tells you the main technical parameters of the medical hyperbaric oxygen chamber

macypanhbot tells you the main technical parameters of the medical hyperbaric oxygen chamber

1. Main technical data

1) Cabin type: one cabin, two rooms and four doors

2) Main technical data and requirements:

Diameter of cabin body: Φ2200mm.

Length of cabin: 6000mm.

Cabin volume: total volume 21m3, main cabin volume 13.8m3, auxiliary cabin volume 7.2m3.

Effective height in the cabin: greater than 1.80m.

Clear ground width: 0.8m.

3) Design pressure: 0.30MPa (4.0ATA).

4) Working pressure: 0.20MPa (3.0ATA).

5) Number of people treated: 6 (4+2).

6) Pressure and pressure control method: manual control.

7) Increasing and decompressing rate:

Minimum compression rate: ≤0.004MPa/min when used as a treatment cabin

When used as a transition chamber ≤0.004MPa/min

Maximum compression rate: when used as a treatment cabin ≥0.050MPa/min

When used as a transition tank ≥0.100MPa/min

Minimum decompression rate: when used as a treatment cabin ≤0.008MPa/min

When used as a transition chamber ≤0.008MPa/min

Maximum decompression rate: when used as a treatment chamber ≥0.050MPa/min

When used as a transition chamber ≥0.080MPa/min

8) Temperature control requirements: Summer: 24-28℃±2℃ Winter: 18-22℃±2℃

9) Cabin noise: When pressurized: ≤65dB (A) When air-conditioned: ≤60dB (A)

The actual noise of the air conditioner is around 55dB(A)

10) In-cabin illuminance: In-cabin illuminance value Ë≥60Lx illuminance unevenness ≤60%.

11) Ambient oxygen concentration in the cabin: ≯21%

12) Oxygen inhalation and discharge resistance: oxygen inhalation resistance≮-50Pa, exhalation resistance≯50Pa

13) Grounding resistance value: ≯2Ω

14) Entry voltage: ≯12V

15) Emergency equipment outside the cabin:

The time from the highest working pressure to 0.01MPa ≤ 2.5 minutes ≥ 1.0 minutes

2. Main supporting equipment

1) 4 sets of cabin airtight doors

Rectangular self-sealing thin shell door

Door clearance size: height 1300mm width 650mm

[Self-sealing thin-shell rectangular door]

The sealed door is processed by a stamping one-step forming process, and the stress distribution of the door panel is uniform. Only a small cabin pressure (0.005MPa) is required to tightly fit the door panel and the fence.

The handle of the cabin door adopts an elastic self-sealing structure, and the handle is gently pulled out, and the handle can step into the self-sealing elastic positioning groove. At this time, the door can be closely attached to the door hole fence. In the process of closing the cabin door, no ancient and complicated mechanical locking device is needed, which is convenient to open and close and has good sealing performance.

2) 6 sets of oxygen inhalation device

Equipped with 6 sets of oxygen breathing machines for hyperbaric oxygen chambers, assembled in a stainless steel plate processing equipment box. Oxygen inhalation and oxygen exhaust devices are assembled into an assembly, which are respectively arranged on the side of the reserved seat, which can be used by patients to inhale and exhaust oxygen in the cabin.

3) 6 sets of seats in the cabin

The cabin seats are designed as fixed luxury seats, arranged in two rows along the bulkhead on both sides of the floor in the cabin. The width and length of the seat are in line with the standard seat size.

4) Observation window

Light transmission size of the observation window: Φ150mm.

There are 4 main cabins, 2 on each side, 2 auxiliary cabins, and 1 on each side.

The observation windows are assembled at the best positions on both sides of the cabin in an even number, and are at the same height; the center elevation of the observation windows is at a suitable height from the ground to facilitate the doctor to observe the patient. Before the formal use, the plexiglass of the observation window is protected by the plastic film. The observation window plexiglass is a transparent, pressure-resistant partition, made of industrial first-class plexiglass, the thickness is 30mm, and the design life is 5000 times of pressure. The medical staff can observe the condition of the patient in any position in the cabin through the observation window while standing on the ground.

5) Camera device The light transmission size is Φ100mm. 2 sets

1 set each for main and auxiliary cabins

6) 3 sets of cold light source lighting devices

2 sets in the main cabin

1 set of auxiliary cabin

7) 4 sets of emergency relief valves for cabins

(1) Location: The emergency relief valve outside the cabin is installed near the console;

(2) Marking and valve handle: the valve body is painted with red eye-catching mark, the valve stem is upward, and the valve handle is pressed down;

The emergency relief valve configured in each compartment can release the pressure of the compartment at a working pressure of 0.2MPa within 2 minutes.

8) Cabin delivery tube

(1) Quantity: 2 sets;

(2) The size of the delivery tube: Φ325×400mm (clear space)

(3) Attachment of the delivery barrel: equipped with 1 balance valve and 1 pressure gauge; 1 set of safety interlock device.

Sealing structure: The outer end cover is equipped with a quick-opening swing ring compression sealing device, and the inner end cover is a special opening and closing system.

The delivery barrel is assembled on the back side of the door hole at the outer end of the treatment cabin, and the delivery time of the delivery barrel is not more than 1 minute.

9) Bulkhead outfitting materials

The bulkheads are outfitted with plastic-sprayed panels, which have high strength, do not change color and will not oxidize. The joints are decorated with aluminum alloy battens, and the structural framework for outfitting is welded with square steel.

10) The ceiling and outfitting materials in the cabin are made of high-grade mirror-finished stainless steel plates: the floor in the cabin is laid with imported ceramic tiles.

11) Seat skirt

The apron under the seat and the side guard of the seat are outfitted with electrostatic sprayed steel plate.

12) 2 sets of multifunctional connecting board (including first-level oxygen inhalation device)

1 set each for treatment cabin and transition cabin

The multi-function connecting board is equipped with oxygen supply flow meter, flow control valve, quick-plug oxygen supply nozzle, sputum suction vacuum meter, connection socket and other devices. It can be used for severe patients such as tracheotomy and nasal intubation. It is connected with a balanced oxygen inhalation and exhaustion helmet and a mobile micro-resistance respirator.

Each set of multifunctional connectors can temporarily connect 2 sets of oxygen inhalation and exhaust devices to increase oxygen therapy for two patients.

13) 1 set of balanced oxygen suction and exhaust helmet

It has the functions of supplying oxygen on demand, automatically balancing the pressure inside and outside the hood, and discharging oxygen appropriately. The CO2 concentration in the helmet can be controlled according to the oxygen flow. It can save the oxygen consumed by the human body exponentially, without consuming the gas in the cabin, and will not increase the oxygen concentration in the cabin environment.

14) Supply and exhaust system

Non-asbestos materials are used for the gasket material of the supply and exhaust system. The pipeline from the air filter to the cabin body is made of stainless steel pipes, which meet the requirements of the latest national standards.

15) Console

(1) Quantity: 1 group (combined type).

(2) Structural form

The longitudinal axis of the main console is parallel to the longitudinal axis of the oxygen chamber body. It adopts piano structure, beautiful and coordinated appearance, and the color of the surface paint is the same as that of the cabin. Arranged in the middle of the oxygen cabin body, the console inspection door is 600mm away from the oxygen cabin body. The arrangement of instrumentation fully takes into account the independence of each system and the concentration of each instrument function.

16) Instrumentation

(1) One oxygen source pressure gauge

(2) One oxygen pressure gauge

(3) Two air pressure gauges in the cabin

(4) 2 precision pressure gauges

(5) Air source pressure gauge 1

(6) 2 sets of temperature controller

(7) One intercom monitoring emergency alarm system

(8) 1 set of CD music device

17) Monitoring system

Color monitor 14 inches 1 set

Color lens 2 sets

2 cameras

Switch 1

18) Oxygen supply control device

Single oxygen inhalation flow meter 6 sets

19) Oxygen meter

2 intelligent oxygen measurement and printing integrated machines

20) 2 sets of gas sampling flow meters

Use with oxygen meter

21) Emergency call device 2 sets

Performance: Non-contact proximity switch .

22) Split type air-conditioning system (external magnetic driving device) 2 sets

[Air conditioner magnetic drive device]

All the electrical components and electrical parts on the original air conditioner were moved out of the cabin, and the motor on the original air conditioner fan was removed and replaced with a magnetic drive device installed outside the cabin. The air-conditioning magnetic drive device can drive the air-conditioning fan in the cabin through the cabin, its power is greater than the actual power of the original air-conditioning motor, and the combined noise of the operation with the air-conditioning fan is less than 55dB(A). During the operation of the device, the personnel in the cabin basically cannot hear the noise, and the gas in the cabin will not leak out under any conditions, and the service life can reach at least a ten-year continuous operation period.

23) Air supply system

(1) 2 sets of oil-free air compressor

0.7m3/min 1.4MPa

(2) 2 sets of gas storage tanks of 5 cubic meters and 1.4MPa

(3) 1 air filter

(4) 1 air cooler

(5) 1 oil-water separator

(6) 4 silencers

24) Oxygen cabin power distribution cabinet

(1) One isolation transformer

(2) Emergency power supply 1 set

(3) 1 air compressor distribution box

(4) 1 set of electrical components and facilities

(5) Cabinet shell 1

25) Water sprinkler system

(1) 2 sets of mechanical manual control valves

(2) 6 sets of deluge valves

(3) 1 set of fire water tank

Main technical parameters of pulse vacuum sterilizer

1. Technical parameters of pulsating vacuum steam sterilizer:

1) Specifications: 1.0 cubic motor double door

2) Interior size: 1790*610*915 (mm)

3) Design pressure: 0.25(-0.1)Mpa

4) Design temperature: 138℃

5) Working pressure: 0.23Mpa

6) Working temperature: 136℃

7) Total power of equipment: ≤35KW/380V

8) Equipment net weight: ≥2000Kg

9) Stroke cycle: about 45min

10) Cooling water consumption: ≤260 Kg /time

11) Dimensions: 2136*1264*1823 (mm)

2. Description of functional requirements: motorized double doors, color touch screen control, Chinese number, curve printer, built-in steam generator.

1) Door and door rubber strips: The door rubber strips are installed on the back of the door, not on the cylinder body to avoid long-term heating of the door rubber strips and prolong the service life.

2) Vacuum pump: bipolar split water ring vacuum pump, belt drive.

3) Pneumatic valve: Imported pneumatic valve, no trouble-free operation for more than 4 million times.

4) Main control system: imported brand programmable controller (PLC).

5) Software program: There are six programs for dressing, equipment, BD, lower exhaust steam, two free settings, set in minutes (0-999 minutes), easy to understand, minimum display value Is 0.1 seconds.

6) Touch screen: 5.0-inch color touch screen, Chinese and digital dynamic display, self-test function, automatic alarm and fault printing record when failure occurs, and can display the temperature and pressure of the jacket and interior at the same time (convenient for timely inspection to ensure safety ).

7) Micro printer: imported printer, Chinese number, curve printing.

8) Door motor: high temperature silent door motor.

9) Pressure sensor: imported pressure sensor.

10) Safety: Double doors are automatically interlocked, pressure and temperature are over-high alarm, dual control, safer, the thickness of the cylinder is 8mm, and the service life of the equipment is guaranteed to be more than 10 years.

11) The programmable controller of the main control system and the original electrical control are separated from the cylinder and installed on the panel side of the equipment, which can be repaired and monitored from the front; avoid long-term heating of the programmable controller of the main control system and the original electrical control , Reduce the failure rate.

12) Vacuum pumps, pipes, electrical appliances and all accessories that need to be repaired must be installed on one side of the equipment, independently suspended to reduce vibration, facilitate maintenance, reduce vibration, and extend the service life of the equipment.

13) The equipment comes standard with 1 sterilization vehicle and 2 loading vehicles.

Main technical parameters of fully computerized multifunctional steam therapy machine

1. A treatment bed with massage function can perform multi-mode and multi-part treatment at the same time.

2. The treatment bed is equipped with two sets of medicine boxes, which can choose multiple medicines for steam bath therapy at the same time.

3. 11 sets of waterproof mattresses can be freely combined to adjust the fumigation position.

4. The treatment bed has multiple steam spray holes and unique steam spray hoods, and can perform up and down front and back, whole body or local moving positioning treatment at the same time.

5. One machine with multiple functions, in addition to steam therapy, it also has bath therapy and massage functions.

6. Adopting the most advanced secondary cycle temperature adjustment technology, the temperature can be adjusted from 38-60℃, the steam volume is large, and the temperature adjustment is accurate.

7. Full computer control, touch buttons, LCD screen, and display of human body treatment diagram.

8. Adopting the most advanced PLD digital control technology, automatic decoction, automatic time control, automatic temperature control, automatic heat preservation and other functions.

9. The equipment has the functions of low water level automatic alarm and shutdown, automatic alarm and shutdown when the time is reached, automatic shutdown with anti-leakage protection, heat preservation in standby state, and high temperature and ultra low temperature control.

10. The bed body is made of high-strength anti-corrosion materials, and the interior is all stainless steel, which is durable, elegant and beautiful.

11. Five groups of ten major acupoints, multi-site and multi-way massage, effectively stimulate acupoints and accelerate drug penetration.

(Massage parts: neck, shoulders, waist, legs and feet, body parts; massage methods: acupressure, flapping, pounding, pounding, slow kneading, circulation mode; massage five levels of intensity (strong, medium, weak).

12. Equipped with patient temperature controller, which is convenient for patients to adjust the treatment temperature by themselves.

13. Free ozone sterilization device, safe and reliable to use.

14. Voltage: 220V/50HZ; power single bed 2000W.

15. Size: Bed: 2000×700×1250mm.